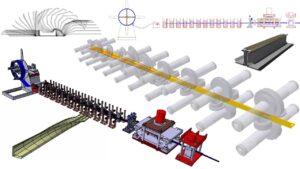

Operations & Training of Roll Forming Machine

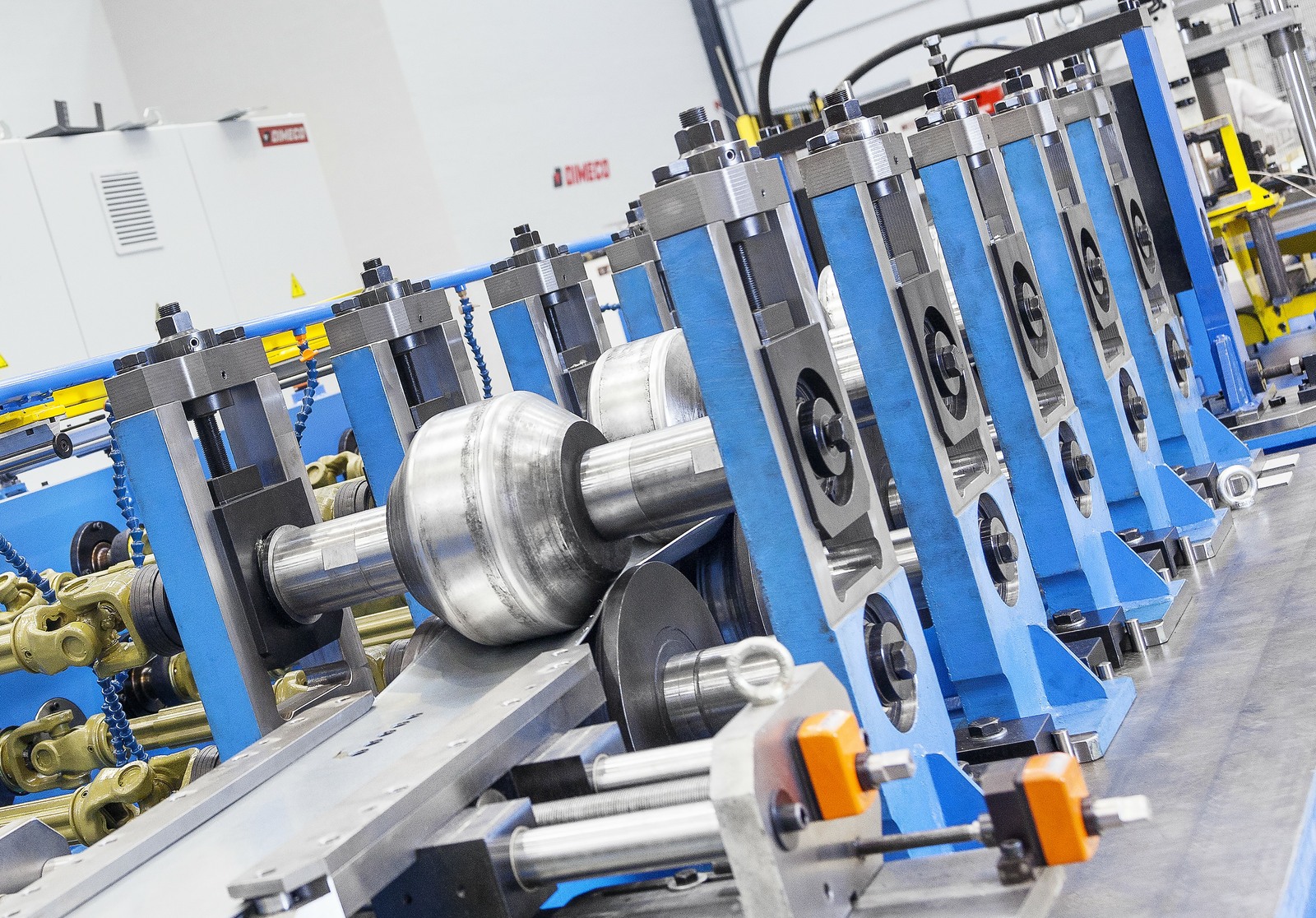

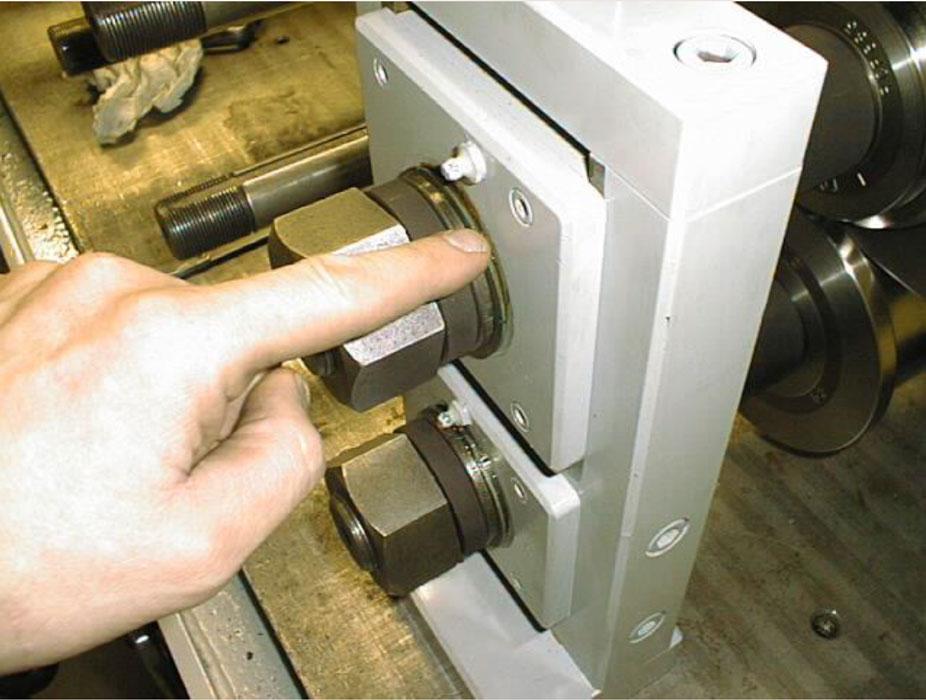

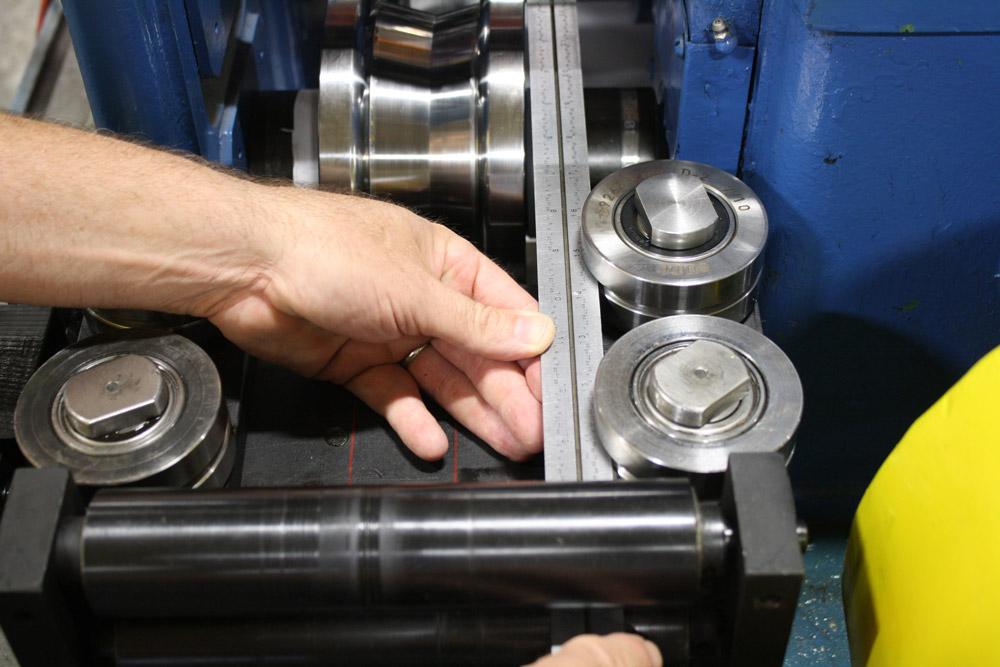

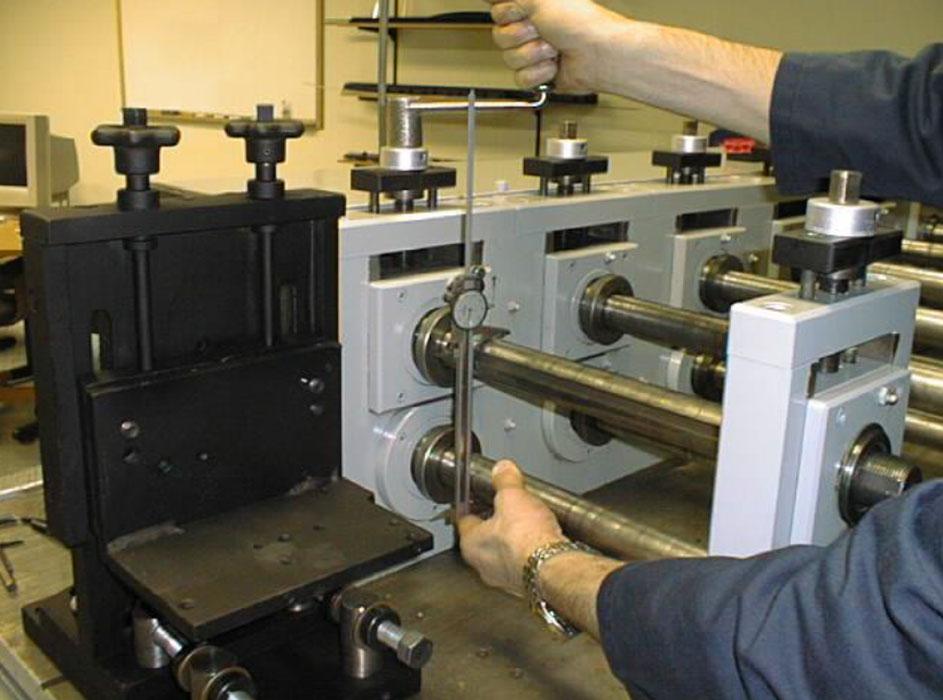

- Setting up a roll forming machine for production involves several critical steps to ensure the proper functioning and quality output of the formed profiles. The process typically includes preparing the tooling, adjusting the roll stands, and calibrating the machine to meet the specific requirements of the desired profile.Operators must carefully align the roll stands, guides, and tooling to ensure that the metal strip passes through the machine smoothly and consistently. Additionally, calibrating the machine’s speed, material feeding, and cutting mechanisms is essential to achieve the desired production parameters.