Modelling & Simulation of Roll Forming Process

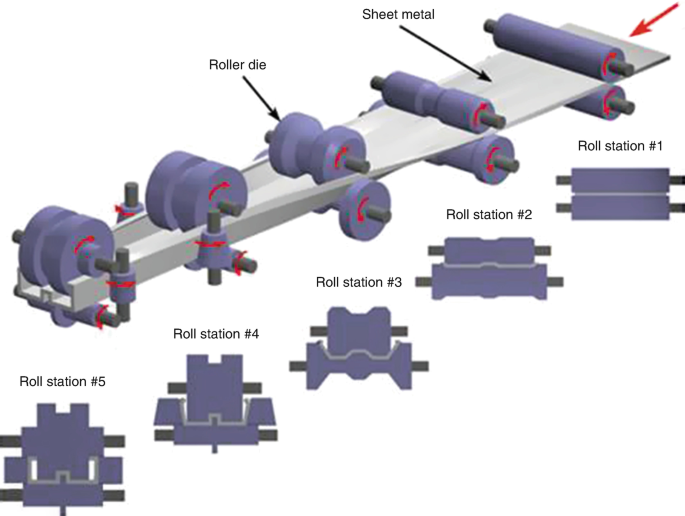

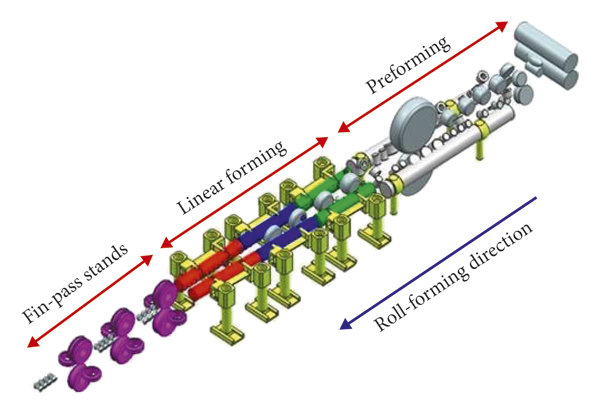

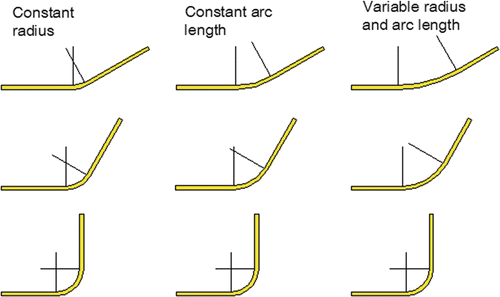

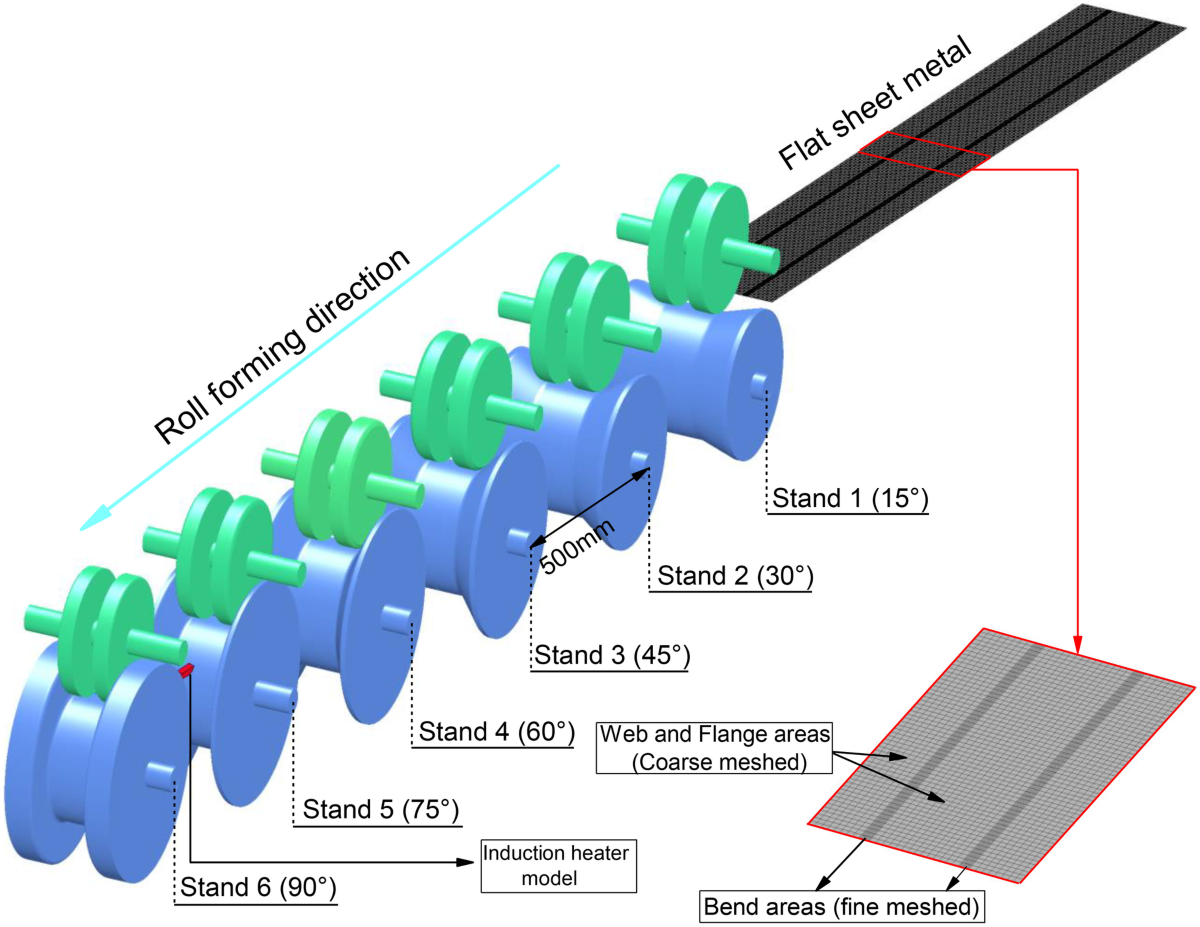

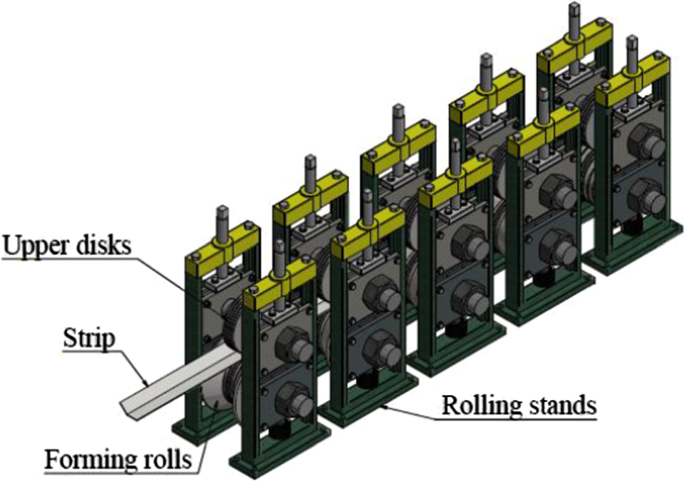

- One of the first decisions to make when a new roll forming line is designed is the number of forming steps needed to produce a profile. This is dependent on the material properties, the cross-section geometry and the tolerance requirement.

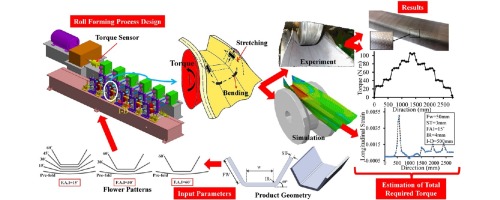

- FE-analysis has been used to validate the design that the CAE system proposes.