Our Roll Forming Capabilities

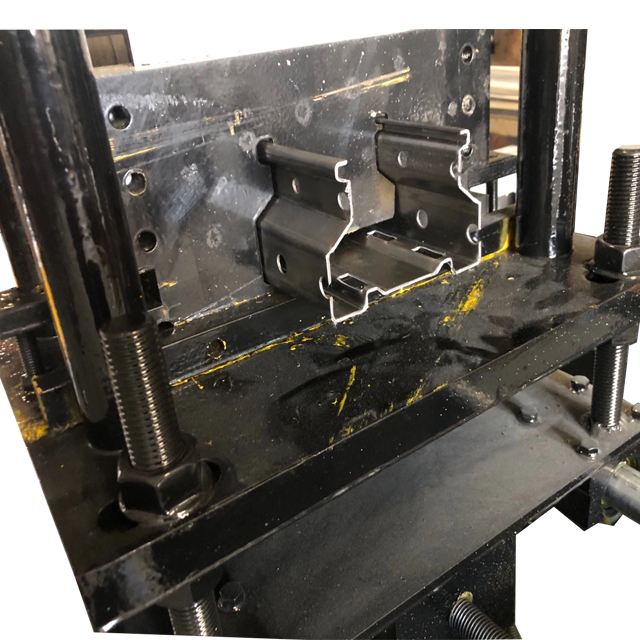

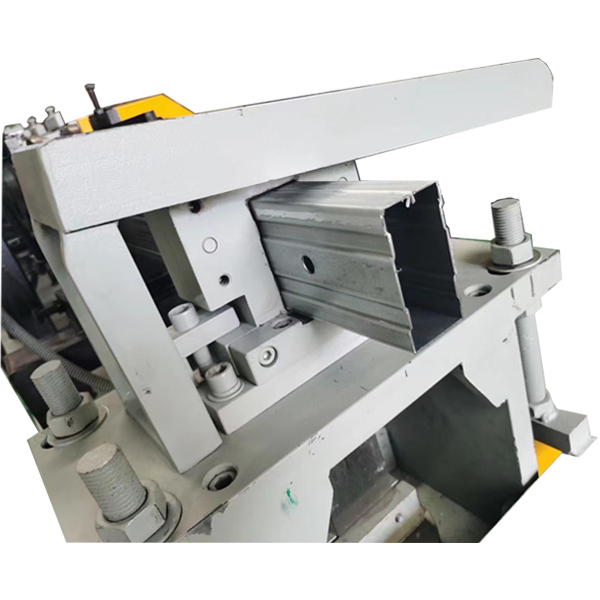

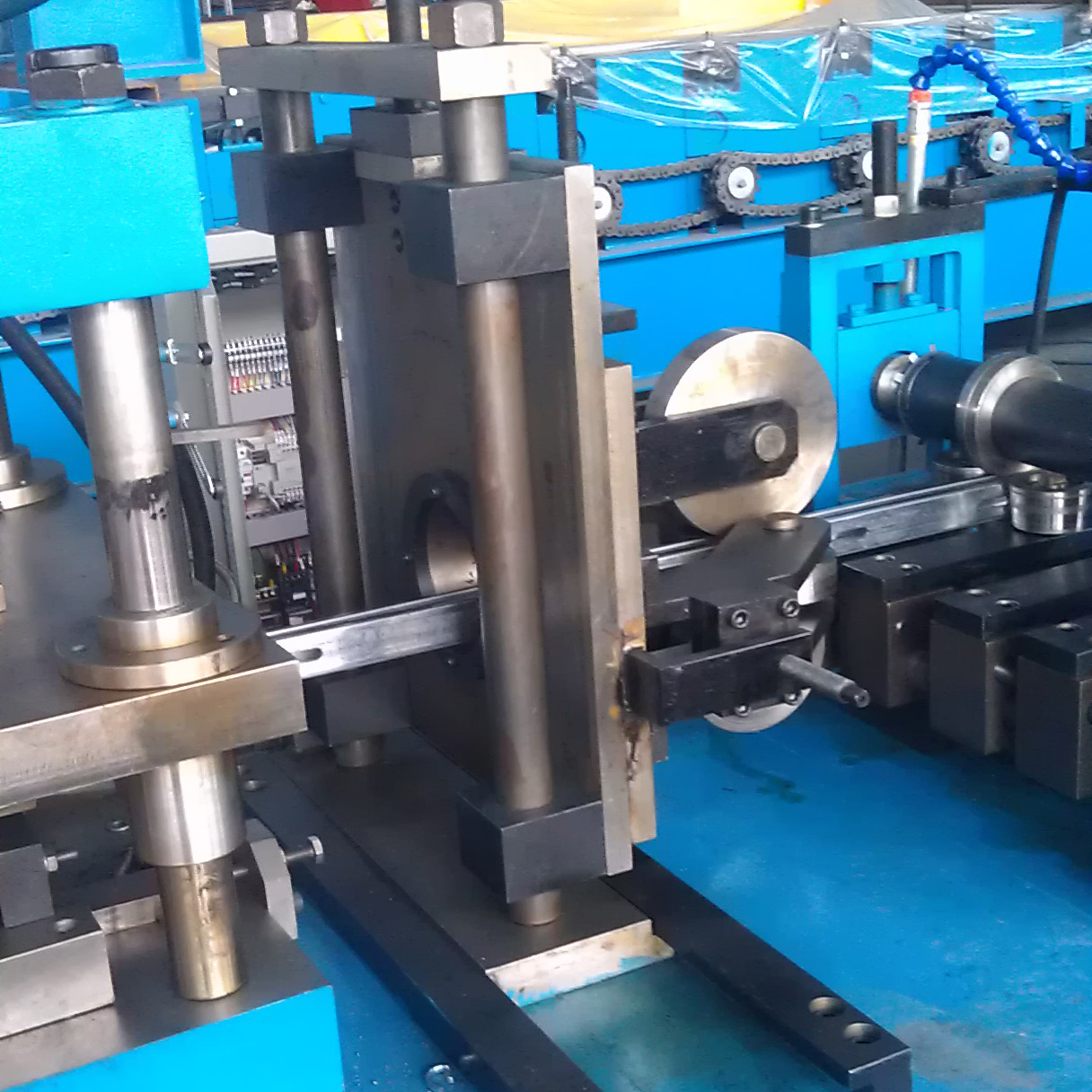

- At VAAM ENGINEERING, we offer sheet metal fabrication and assembly services.

- Our team of experts can handle virtually all types of metal assembly to your unique requirements.

- We use the best tools and processes to achieve accurate and highly durable parts, with no room for inconsistencies.

- From prototype to production, Vaam Engineering remains your reliable partner for your various metal assembly needs.