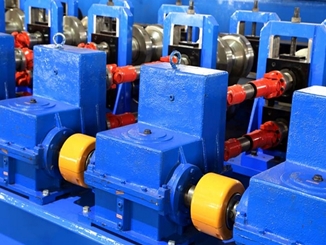

Highway Guardrail (W Beam) Profile Roll Forming Machine

Work Flow

Decoiler–punching (if need holes or logo)–feeding–roll forming–cutting–product table

Technical parameters for the whole production line:

| Formed Material | HR Sheet,Galvanized Sheet | Thickness: 2.6-3.5mm | ||

|---|---|---|---|---|

| Main Body | Roller station | 18 TO 22 Raws (As per Requirement) | ||

| Diameter of shaft | 75mm solid shaft | |||

| Material of rollers | D2 quenching treatment | |||

| Machine body frame | Mild Steel welded | |||

| Drive | Gear Drive | |||

| Dimension(L*W*H) | 4.8m×0.6m×1.2m (Customize) | |||

| Weight | Approx 2.5 tonne | |||

| Decoiler | Hydraulic Automatic/Manual decoiler | hydraulic/manual decoiler with higher speed Max width 300mm Inner diameter -460-510mm Max loading capacity 1000kg Manual operating type manual expansion to tighten the coil Break down drive whole line stop while decoiler idle | ||

| Cutter | Automatic | cr12mov material, no scratches, no deformation | ||

| Power | Motor Power | 45 KW | ||

| Hydraulic system power | 22 KW | |||

| Control system | PLC | Automatic production of the whole machine. Can set batch, length, quantity, etc. Frequency converter Silin ,Taiwanese PLC Touch screen weinview Taiwanese Profile length cutting forming machine stops then cut Operational controller: touch screen knob switch Brake down and so on Power supplier 380V 50Hz 3phase | ||

| Forming Speed | 10-12m/min(customized) | Speed is adjustable according to customer’s request | ||

Forming Rollers | Forming Station 18-22 nos Forming Rollers material Cr12 Forming Rollers hard treatment HRC 58-60 Shaft of roller Diameter 75mm Shaft material 40Cr,heat treatment,refine grinded Machine frame: steel welding Main sidewall thickness 25mm Machine driven by universal joints via gearbox Roll forming motor 5.5kw with frequency inverter controller Gearbox RV worm gearbox |