Cable Tray Profile Roll Forming Machine

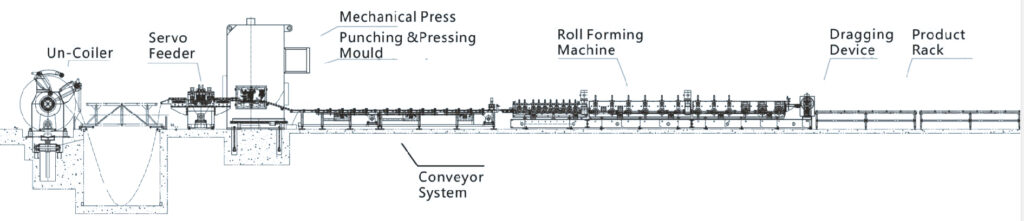

Work Flow

Uncoiling –leveling- Looping—Feeding—punching —Roll forming—Cutting –Discharging

Equipment overview:

Double cantilever gear drives, the producing width of machine is adjust continually, it is possible to change the width and height.

Rolling stations is 20 steps ,the main machine consists of AC motor,reducer,high precision liner rail, transmission box on left and right, horizontal adjustment system and rolling moulds. The machine base and transmission adopts welding structure , with hardness treatment, the material of roller is D2 steel.

The roll forming craft is made by the special Germany cold roll forming program; the craft is also made the FEA analysis and check. The structure of the rollers is combined, so the line speed difference and resisting force of roll forming is small. The sheet is easy to feed. All these assure the accuracy and stable of the roll forming.

| Formed Material | CR,HR Sheet;Galvanized Sheet | Thickness: 1.2-3.2mm |

|---|---|---|

| Strength | ≤350 Mpa | |

| Coil internal diameter | 500,600 MM | |

| Coil weight | 5 Ton | |

| Main Body | Roller station | 18 TO 22 Raws (As per Requirement) |

| Diameter of shaft | 65mm solid shaft | |

| Material of rollers | D2 quenching treatment | |

| Machine body frame | Mild Steel welded | |

| Drive | Gear Drive | |

| Dimension(L*W*H) | 6000x1000x1200 mm (Customize) | |

| Weight | Approx 6 tonne | |

| Decoiler | Hydraulic Automatic/Manual decoiler | hydraulic/manual decoiler with higher speed |

| Cutter | Automatic | cr12mov material, no scratches, no deformation |

| Power | Motor Power | 7.5KW |

| Hydraulic system power | 5.5KW | |

| Control system | PLC | Automatic production of the whole machine. Can set batch, length, quantity, etc. |

| Forming Speed | 10-12m/min(customized) | Speed is adjustable according to customer’s request |