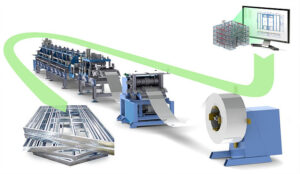

In the world of roll forming, mastering the right tools and techniques is crucial to achieving consistently high-quality, high-performing custom components. The expert team at Roller Die + Forming utilizes a diverse toolbox of advanced equipment and cutting-edge methodologies, enabling them to deliver unmatched precision, durability, and efficiency in every roll formed product.

Prepare to take a deep dive into the world of roll forming, uncovering the advanced machinery, tooling solutions, and methodologies that differentiate Roller Die + Forming from its competitors. By understanding the intricacies and nuances of their roll forming toolbox, you will gain valuable insights into what sets Roller Die + Forming apart as a leader in the custom roll forming industry.

Unlocking Exceptional Roll Forming Results with Roller Die + Forming

Roller Die + Forming’s extensive roll forming toolbox, which encompasses advanced machinery, innovative design and simulation techniques, rigorous quality control processes, and a highly skilled workforce, enables them to create custom roll formed components of the highest quality and performance. With their commitment to precision and innovation, Roller Die + Forming ensures that every project exceeds clients’ expectations and meets the most stringent requirements.

Are you ready to bring your custom roll forming project to life with unmatched precision, durability, and efficiency? Contact Roller Die + Forming today to discuss your unique requirements, and let our team of experts leverage their extensive aluminum roll forming toolbox to drive your project towards outstanding success